Introduction

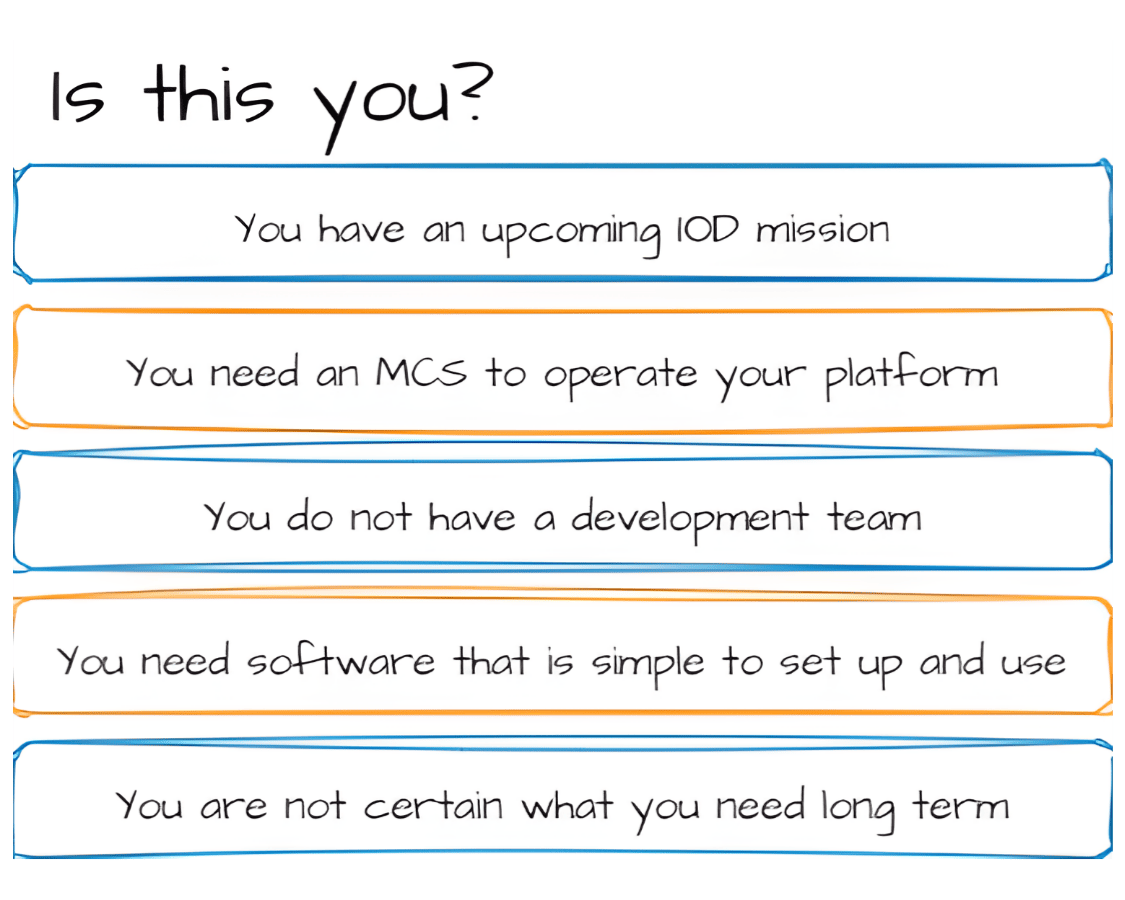

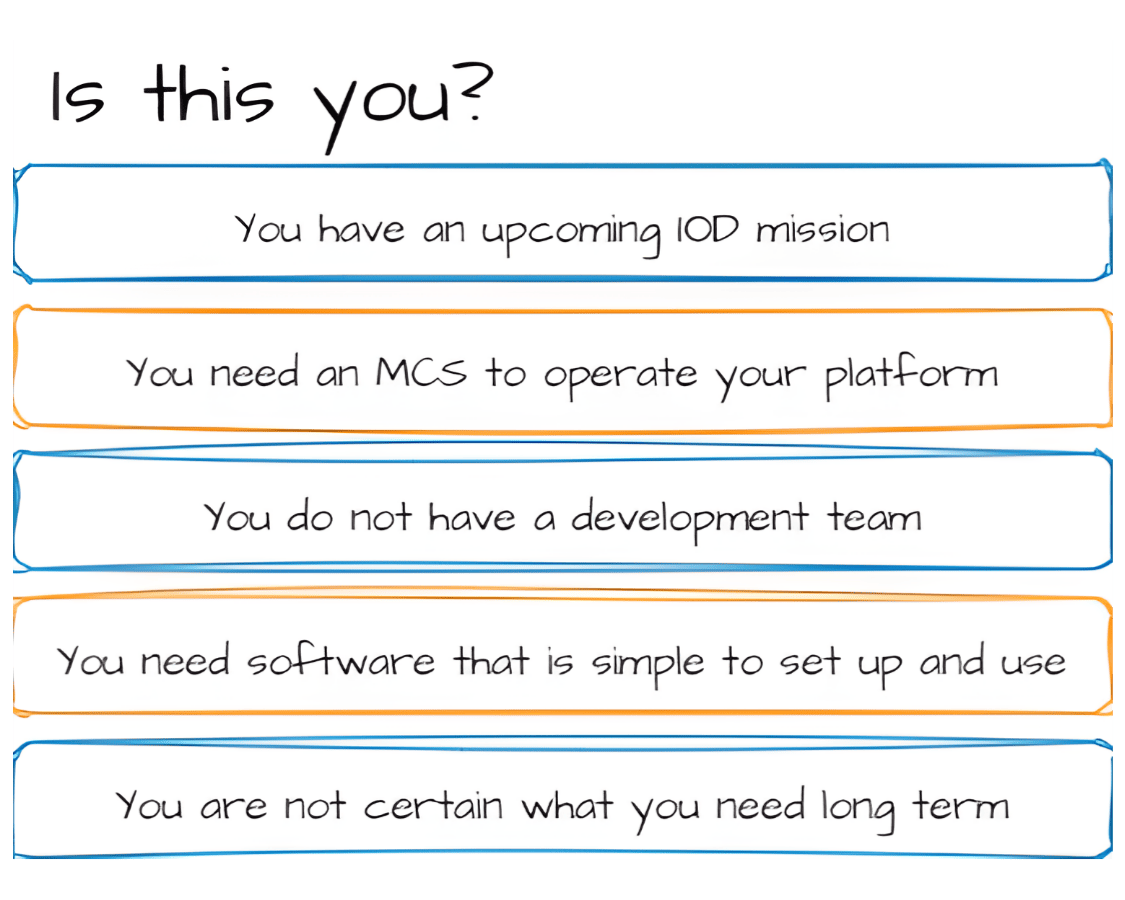

For satellite operators in their mission design phase, there are a lot of unknowns. The challenge is that the choices that you make today have significant impacts down the road, and it’s difficult to understand what the best decisions are for both today and tomorrow.

This blog challenges the idea that you should have all the answers and instead, highlights why flexibility and adaptability are king, and directly apply to your choice of an MCS platform.

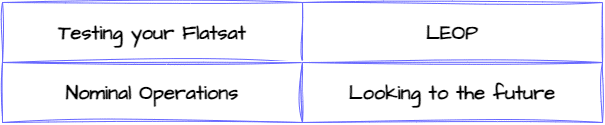

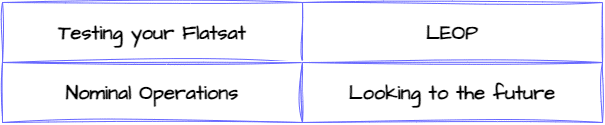

Decision milestones: from flatsat testing to the future

Let’s outline the key decision milestones that you will face. From your first test of your flatsat to the nominal operations of your satellite and looking ahead to the future.

At this stage, you want to test that everything works as expected with your flatsat. The challenge is that you need an MCS solution ASAP, either a complete MCS or a simplified MCS for flatsat testing purposes. You need to know if your MCS works well, as this will be something that you will use in the long term.

Your company does not have a dedicated development team to build an MCS from scratch, so your options appear to be to either go for the MCS that came with your satellite platform provider, or to get a commercial off-the-shelf solution (COTS).

This is a short term or long term decision. Let’s explore the impact of your choice.

Problem #1 — “I see small issues in the MCS UI”

Traditional MCS

You are testing the flatsat and you start to see issues with how your telemetry is displayed. You need to monitor certain values from your payload, but the MCS software has not been designed to cover these. You decide to speak to your MCS provider, but they cannot provide any guarantees if this will be added as a new feature in the future…

MCS lite

You have the source code, which means that you can easily make the small changes that you need with little expertise required.

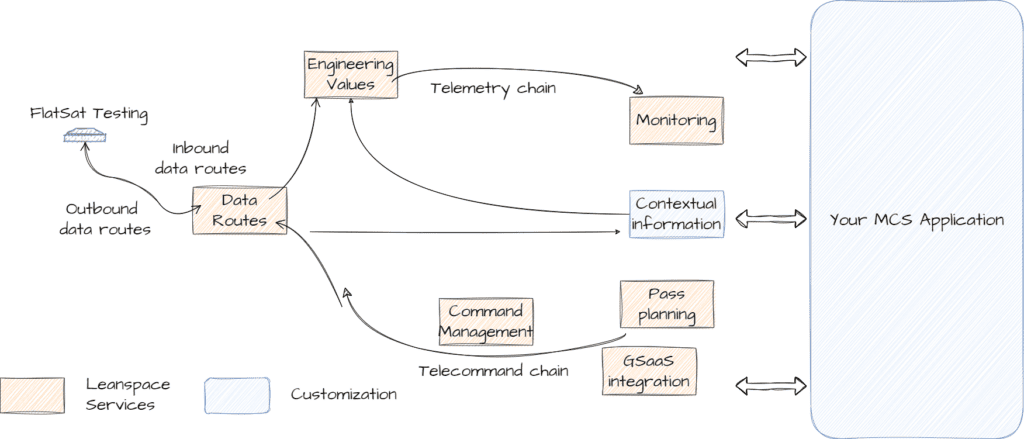

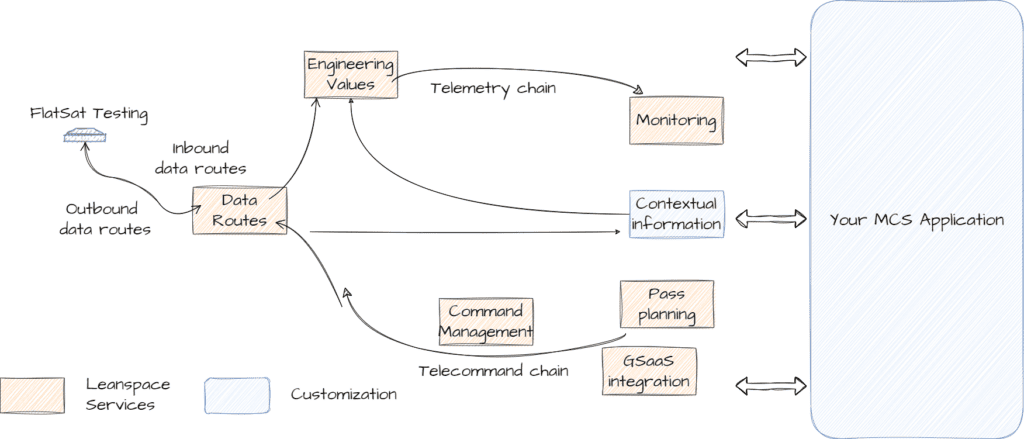

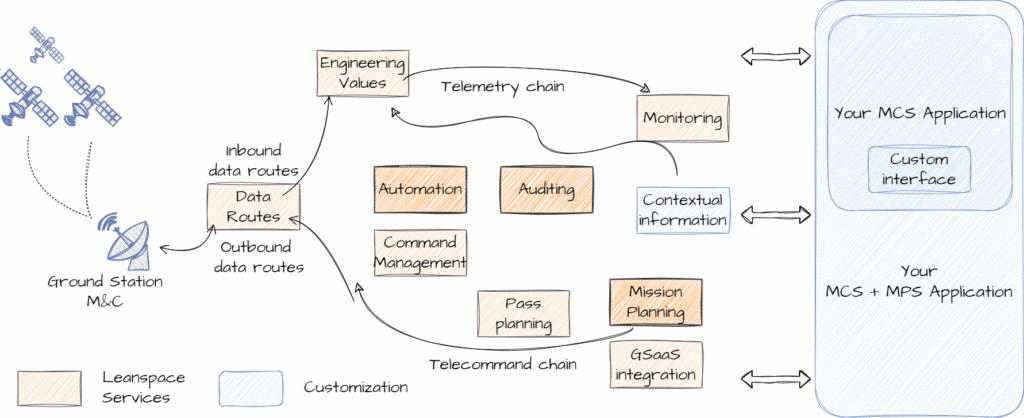

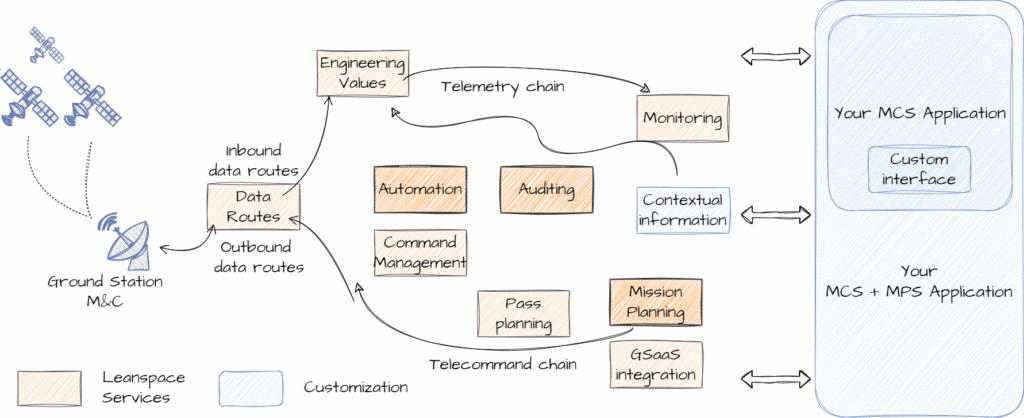

As seen in the image below, MCS lite comes as a package powered by multiple Leanspace services, ready to use for your first mission. As you’ll see later in this blog, this can be expanded for your IOD and beyond.

Congratulations, you’ve made it to orbit and have located your satellite! You have established two-way communications and are in the process of continued testing and configuration of your satellite.

Problem #2 — “I want to store more than my engineering values from the satellite, such as from ground stations, and other contextual data”

You’ve discovered that there is a lot of data that should be tracked, analyzed, and audited. This includes telemetry to help understand what the satellite was doing at the time of transmission and how well it executed on your commands. Other types of data include the signal-to-noise ratio to verify the link performance, and the frames transmitted and received to quickly detect if there are issues.

Traditional MCS

While your MCS does track many engineering values from your telemetry, there is no customization available for your use case. Your workaround is to send this extra information to a spreadsheet, where it can be looked at another time.

MCS lite

Leanspace’s Metrics APIs allow you to easily ingest any additional metrics as you see fit. For instance, you can store engineering values in their raw form, transform and validate them to ensure a quality data ingestion that fits your use case.

You can also pull and push data to and from Leanspace using multiple sources and inputs/outputs, while being able to display them together or separately as needed. As you will discover later in this blog, having easy access to your data is helpful, both for when you want to optimize, but also for when you need to resolve issues.

Problem #3 – “I had an anomaly, I need to investigate the issue”

You’ve started to notice that your satellite is producing a recurring anomaly when executing one of its main functions. As a consequence, it’s halting your payload operations.

To diagnose the issue, you need to audit your satellite’s engineering values, or metrics, to assess its operational health. You also require a history of all transmitted commands to correlate and pinpoint the exact issue.

Traditional MCS

The platform only stores a limited history of your telemetry and commands, Sent and Acknowledged, but it is not enough to debug the anomaly – you need more data. Your raw data containing telemetry and telecommands are sourced from multiple locations and it requires a lot of effort to bring everything together.

MCS lite

By default, all of your sent commands and engineering values are stored centrally on the Leanspace Platform. At a glance, you know the status of the satellite from the received telemetry and all the commands sent or executed on board, including the operator who sent them. You can choose how much of this information needs to be displayed within MCS lite or you can choose to analyze the data directly on Leanspace’s configuration manager.

Problem #4 – “Nominal operations are performing well; it’s now time to optimize them.”

Congrats, your technology works! Now it’s time to optimize your operations so that you can get more from your payloads and reduce operational costs. This involves taking advantage of automated workflows and optimizing your satellite’s use of onboard resources.

Traditional MCS

As the MCS has a limited number of API endpoints, you’re spending a lot of time and resources on developing improvements and workarounds on it to fit your use case, with no guarantees that you will be able to use these after the IOD. It’s very likely that your work will have to be continuously modified as you scale and modify your operations.

MCS lite

For the MCS lite, API endpoints are not an afterthought, they are the foundation of the Leanspace Platform. They have been designed for you to quickly set up and start using them, with the ability to add extra Leanspace services to achieve full end-to-end automation: from request to payload data downlink and delivery; and optimize onboard resources to increase the number of images that you can take per day.

In this regard, you are not locked in or limited. Instead, you’re enabled and encouraged to expand the functionality of your MCS for your IOD today and for the missions that follow.

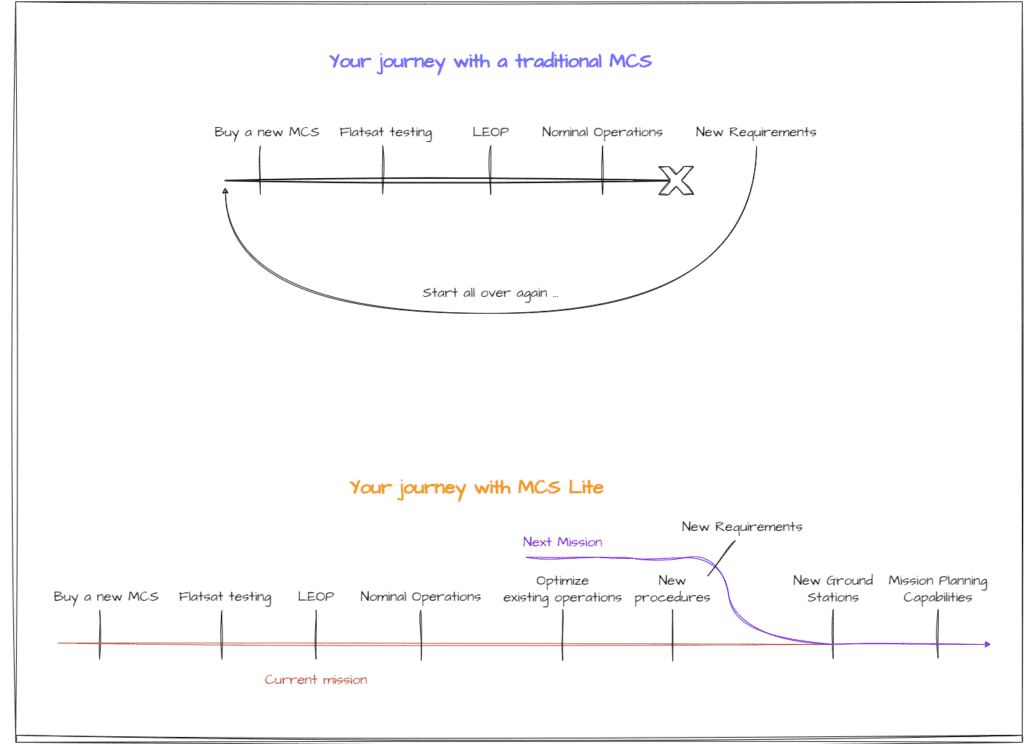

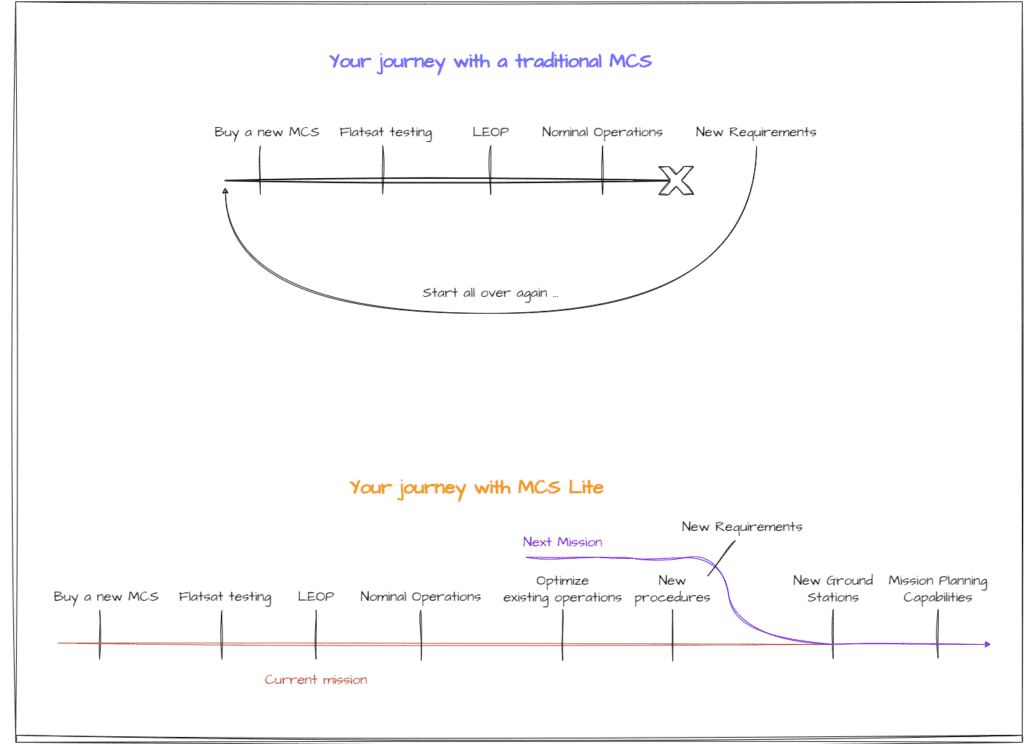

In the future, you expect to be operating multiple satellites. With the increase of satellites comes an increase in complexity. This is the point where you need to take all of your learnings from the IOD and start growing towards your full potential.

Problem #5 – “I want to test new ground segment development features that will be needed for future missions”

With all of this potential comes the need for a better ground segment to support future missions.

Traditional MCS

It’s at this point that you realize that you need a better MCS software. One that has improved functionality and flexibility to resolve the challenges you had in your demonstrator mission.

The problem with this is that your original MCS data needs to be migrated to the new one and it’s at this point where you need to start from scratch and rebuild your configuration for the new MCS.

MCS lite

MCS lite is powered by the Leanspace Platform, which inherently supports scalability for large satellite constellations. The platform’s design enables this scalability, allowing for the efficient management of extensive networks of satellites, including the ability to add satellites and flatsats to your MCS.

All of the work that your team did, such as adding customizations and automating workflows, can be reused in the new mission. This also means that your team is comfortable with using Leanspace, allowing for smooth transitions to add new functionality!

As seen in the image below, the overall architecture has been modified to fit the decision milestones outlined in this blog.

For your newest mission design, you have seen that you can meet all of its complex requirements by taking advantage of Leanspace’s additional services. In the short term, you can add capabilities like automation to optimize your operations. When you are seeking to perform missions with a little more complexity, MCS lite can be extended with both mission planning and flight dynamics, which enables it to become a fully integrated, ground segment software solution.

In essence, you have shaped the MCS lite to fit your use case; and by the end of your IOD mission, it has become your foundational MCS. This has been achieved without the need for a big development team or being constrained to a certain satellite manufacturer.

Conclusion

Overall, MCS lite has been designed to provide the flexibility when you need it most. There’s no longer a trade-off between choosing a simple MCS to operate your first mission and building a complex ground segment for your future requirements. With MCS lite, you can have both.

Does this resonate with you? If you are liking what you are reading, feel free to click the button below and talk to Peter Healy, our business development manager who will be delighted to walk you through how MCS lite can fit your use case.